TECAFORM® is a semi-crystalline thermoplastic offering high strength, stiffness and toughness. TECAFORM® is resistant to hot water, hydrocarbons and solvents, and it possesses good bearing and wear properties. It is available in natural and black grades. TECAFORM® is commonly used as bushings, rollers, wear strips and other applications requiring a combination of strength, low moisture absorption, chemical resistance and dimensional stability. Natural colored sheets are FDA compliant.

TECAFORM® is a semi-crystalline thermoplastic offering high strength, stiffness and toughness. TECAFORM® is resistant to hot water, hydrocarbons and solvents, and it possesses good bearing and wear properties. It is available in natural and black grades. TECAFORM® is commonly used as bushings, rollers, wear strips and other applications requiring a combination of strength, low moisture absorption, chemical resistance and dimensional stability. Natural colored sheets are FDA compliant.

- No centerline porosity

- Low moisture absorption

- Excellent machinability

- Good combination of mechanical properties

- Chemical resistance to fuels and solvents

TECAFORM™ is resistant to aqueous solutions with pH values ranging from 4 to 14. - Good wear and abrasion properties

- Good dimensional stability

- Good property retention at elevated temperatures

- Blue Grades are also manufactured from resin that is FDA compliant

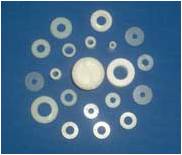

TECAFORM® is used in a wide variety of industrial applications requiring good strength and toughness, dimensional stability, wear resistance and the ability to operate in a wet environment with little absorption. Material handling, machinery and fluid handling are some of the common industries utilizing TECAFORM®’s combination of properties. Typical applications are gears, wear strips, bushings, pump parts, fittings and rollers.

| Properties | Condition | Value | Test Method | Comment | ||||

|---|---|---|---|---|---|---|---|---|

| Mechanical | Modulus of elasticity (tensile test) | @ 73°F | 380,000 | psi | ASTM D 638 | |||

| Tensile strength at yield | @ 73°F | 8,800 | psi | ASTM D 638 | ||||

| Elongation at break | @ 73°F | 25 | % | ASTM D 638 | ||||

| Flexural Strength | @ 73°F | 11,000 | psi | ASTM D 790 | ||||

| Modulus of Elasticity (flexural test) | @ 73°F | 360,000 | psi | ASTM D 790 | ||||

| Compression strength | 4,500 | psi | ASTM D 695 | |||||

| Impact strength (Izod) | @ 73°F | 1.0 | ft-lbs/in | – | ||||

| Rockwell hardness | @ 73°F M Scale | 86 | % | ASTM D 785 | ||||

| Coefficient of friction | Dynamic, 40 psi, 50 fpm | .21 | ASTM D 3702 | |||||

| Wear rate | 40 psi, 50 fpm | 65 x 10-10 | in3-min/ft-lbs-hr | ASTM D 3702 | ||||

| Thermal | Melting temperature | 329 | °F | – | ||||

| Deflection temperature | @ 66 psi | 316 | °F | ASTM D 648 | ||||

| Deflection temperature | @ 264 psi | 230 | °F | ASTM D 648 | ||||

| Service temperature | Intermittent | 285 | °F | – | ||||

| Service temperature | Long term | 195 | °F | – 1) | 1) per UL746B | |||

| Thermal expansion (CLTE) | 4.7*10-5 | in/in/°F | ASTM D 696 | |||||

| Electrical | Volume resistivity | 1.0 x 1014 | Ω*cm | ASTM D 257 | ||||

| Dielectric strength | 500 | V/mil | ASTM D 149 | |||||

| Dissipation factor | @ 60 Hz, 73°F | 0.001 | % | ASTM D 150 | ||||

| Dielectric constant | @ 60 Hz, 73°F, 50% RH | 3.7 | % | ASTM D 150 | ||||

| Other | Moisture absorption | @ 24 hrs, 73°F | 0.22 | % | ASTM D 570 | |||

| Moisture absorption | @ saturation, 73°F | 0.80 | % | ASTM D 570 | ||||

| Flammability (UL94) | UL 94 | HB | % | 2) | 2) at 1.5mm thickness injection molded sample | |||

| This information is only to assist and advise you on current technical knowledge and is given without obligation or liability. All trade and patent rights should be observed. All rights reserved. Data obtained from extruded shapes material. TECATRON®PPS – Ensinger Industries, Inc. |

||||||||